Brief

Design and manufacture 10 identical products for sale in a local gift shop.

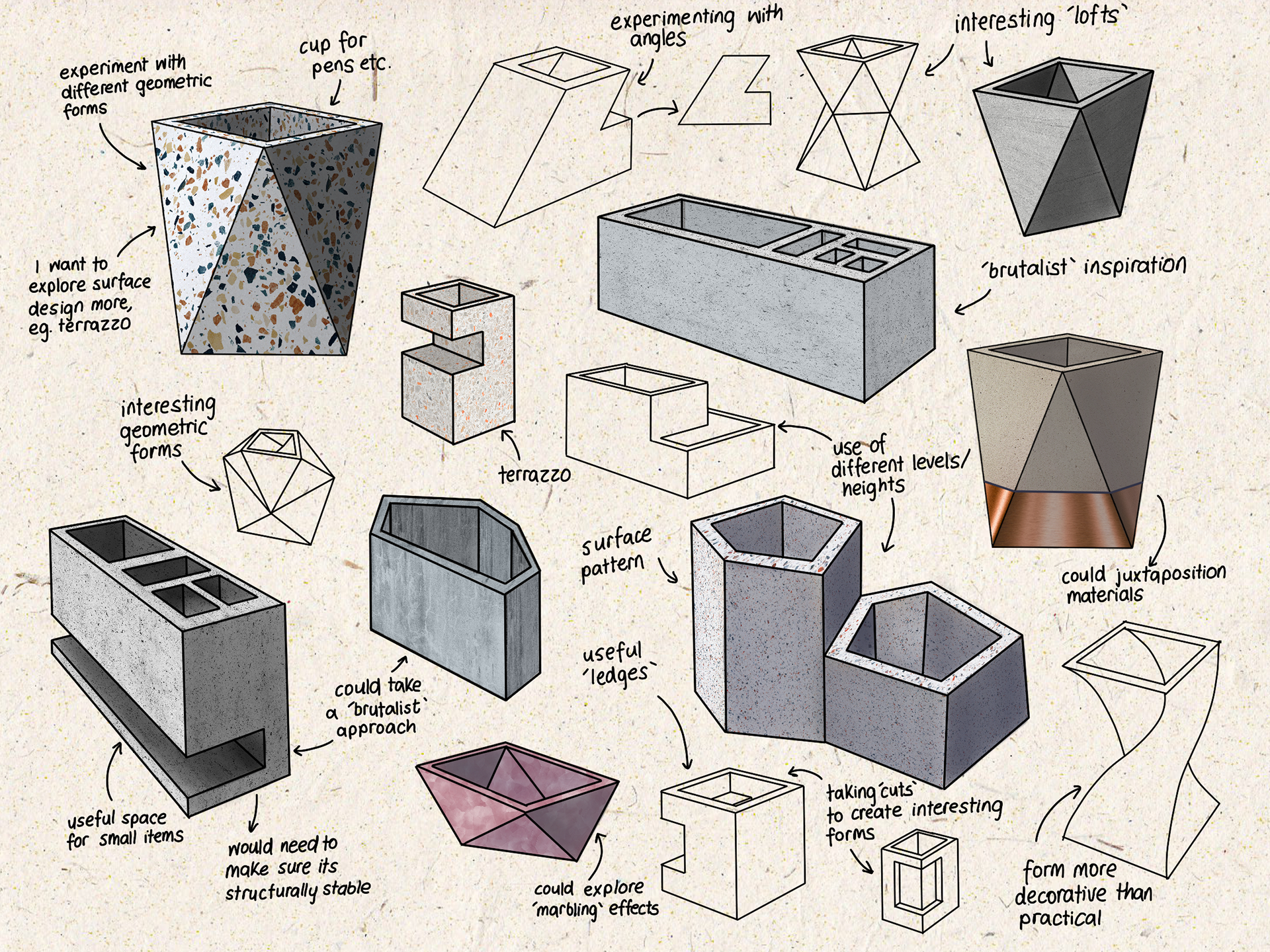

Concept Generation

After exploring a range of different product ideas that would sell well in the shop environment, I was drawn to designing a desk tidy. I wanted to create a functional yet beautiful item.

Production

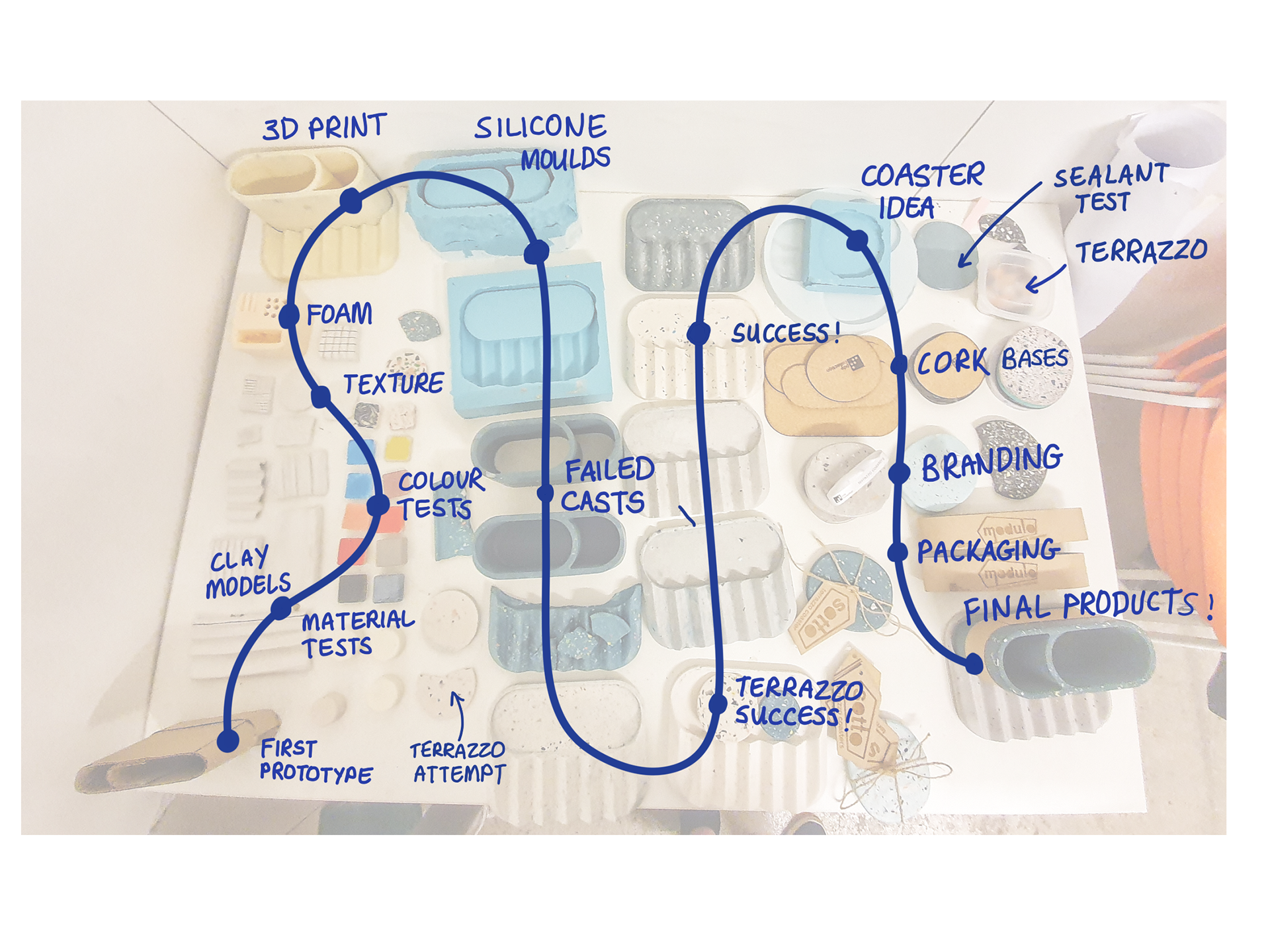

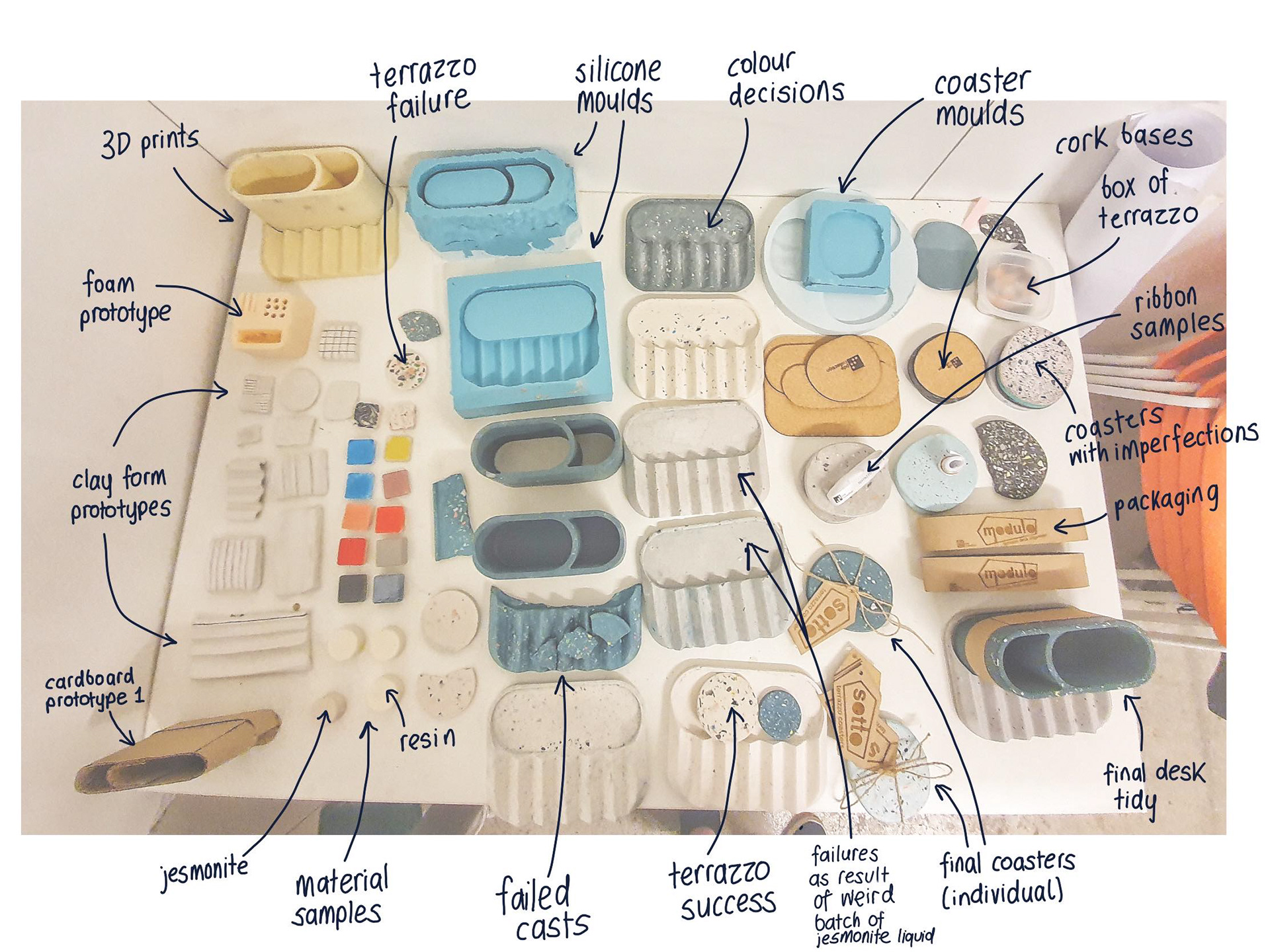

I created my final silicone moulds using a 3D print of my design. The 3D print was sanded to ensure a smooth finish.

Jesmonite was measured, mixed with terrazzo and poured into the moulds. Each part was left for a minimum of 30 minutes before removal.

After removing each part from the mould, the terrazzo would be hidden. Therefore each part had to be intensely sanded using 60 to 320 grit sandpaper to bring through the colours of the terrazzo.

Finally, a laser cut and etched base was glued onto each product.

3D Prints

Silicone Mold

Silicone Mold (pt 1)

Making Terrazzo

Breaking Terrazzo

Production Line

Sanding Process

Base Component

Cork Bases

Sotto

To make the most of excess Jesmonite, I created a collection of terrazzo coasters to sell alongside the desk tidy. This also allowed me to experiment further with colours, size and quantity of terrazzo whilst still producing desirable products to sell.

Each coaster was sealed using an acrylic sealant to ensure longevity in the event of liquid spillages.

Opening Night

All Sotto coaster sets sold out on opening night alone. Within a week, all my products sold out.